Performance and processability

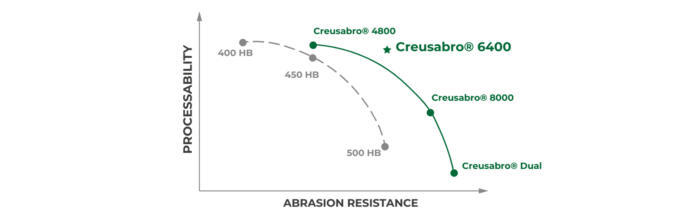

The latest addition to the Creusabro range, Creusabro 6400 is designed to meet the needs of builders and users looking for abrasion-resistant steel that outperforms conventional 450 HB steels or is easier to work with than 500 HB steel.

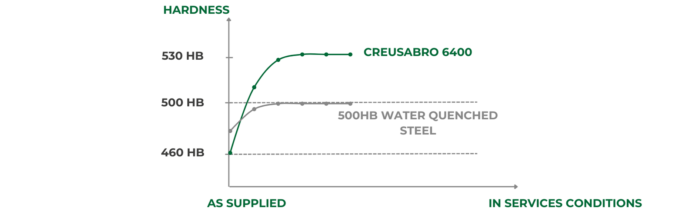

The TRIP effect allows it to achieve a hardness of 530 HB in use while offering better processability than conventional 500 HB steel.

Creusabro® 6400 is designed to offer the best possible combination of wear resistance and exceptional processability.

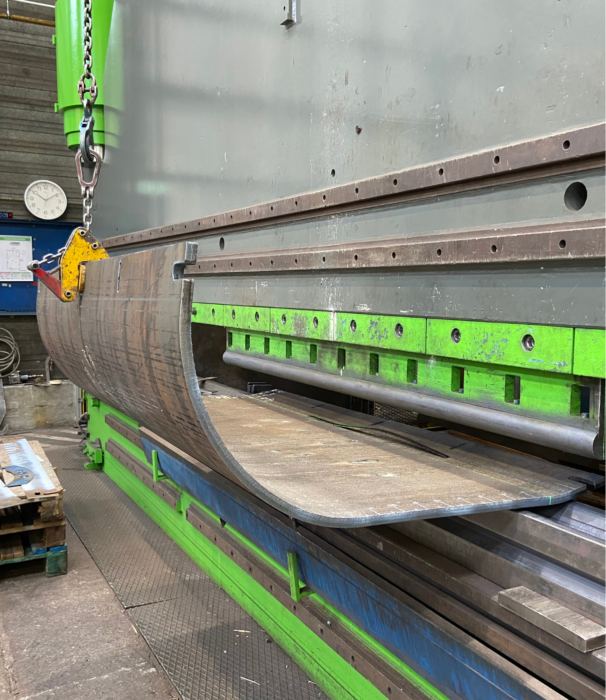

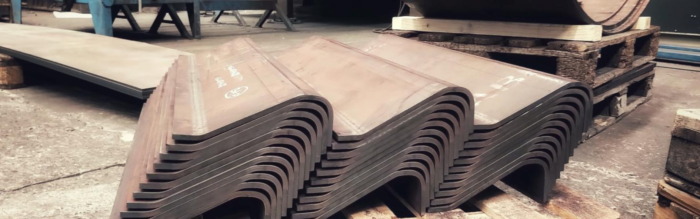

The specific metallurgy and moderate hardness of Creusabro® 6400 in its delivery state make processing operations such as cutting, machining, or forming easier compared to conventional 450HB and 500HB steels.

Exceptional Properties

- Self-hardening capability (up to 70 HB)

- Unparalleled processability for a 530 HB steel

- Weight savings and payload improvement

- 100% sourced from recycled steel in an electric furnace.

TRIP EFFECT

Creusabro® steels significantly enhance their wear resistance in service through a surface hardening effect of up to +70 HB, resulting from local plastic deformations caused by the impact or pressure of abrasive particles

TRIP Effect :

• Austenite transformed into hard martensite

• Absorption of impacts and filling of microcracks through the transformation of austenite into martensite

• Matrix containing very hard microcarbides

• Delays surface cracking and particle detachment

Mechanical Properties

| Hardness | Tensile Strength RE | Tensile Strength RM | Elongation | Typical resilience |

| 460 → 530HB | 1000 MPA | 1450 MPA | 12% | 50J à -20°C, Garantie 27J |

Chemical analysis

| C | S | P | Mn | Ni | Cr | Mo |

| ≤ 0.22 | ≤ 0.003 | ≤ 0.02 | ≤ 4.2 | ≤ 0.25 | ≤ 0.25 | ≤ 0.2 |