Creusabro® 4800 : wear resistant steel

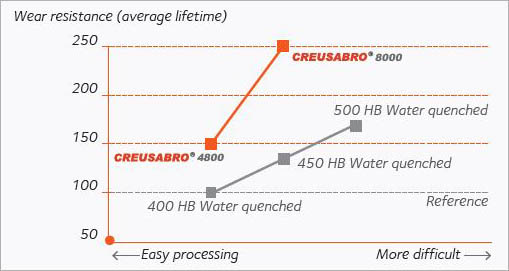

CREUSABRO® 4800 is an abrasion resistant steel with a wear resistance 40 to 50% higher than conventional 400 HB water quenched steels.

Beyond hardness, the mechanical properties of Creusabro are the result of an enriched metallurgy (Chromium, Nickel, Molybdenum and Titanium), as well as a specific heat treatment.

Creusabro® wear resistant steel is designed to offer the best balance between exceptional wear resistance and processability.

Unique metallurgical concept:

Abrasion resistance is not only associated with the hardness of a steel in its delivery condition.

The chemical composition and metallurgical structure strongly influence the performance in service.

The metallurgical structure resulting from the chemical composition and production process of Creusabro contributes strongly to increase wear resistance through the phenomena described above.

TRIP effect:

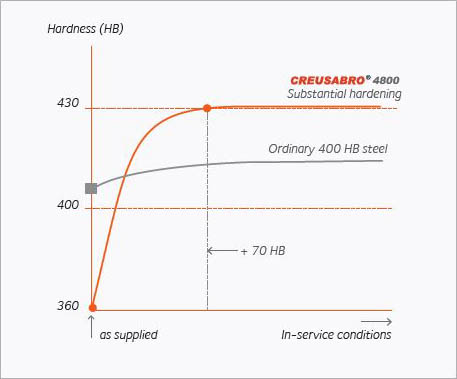

The moderate hardness of Creusabro® 4800 abrasion resistant steel in the delivery state makes cutting and bending operations easier than with conventional water hardened steels.

In service, Creusabro® 4800 significantly increases its wear resistance through surface hardening (+70 HB) under the action of local plastic deformations caused by the impact of rocks or under the pressure of abrasive particles.

Application:

Creusabro® 4800 is the ideal product for applications in mining and quarrying, cement works, steelworks, public works, agriculture and recycling.

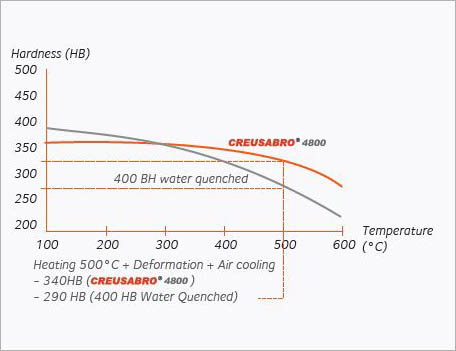

This grade is resistant to hot abrasion up to 450°C, whether in wet or dry conditions, with sliding or impact, whereas conventional water-quenched steels are restricted to 250°C.

High temperature properties:

The composition of Creusabro® and in particular its Nickel and Molybdenum content provides a high resistance to hot softening superior to conventional water quenched 400 HB steels

Thus Creusabro® can be hot worked at 450 – 500°C (840 – 930°F), forming thick plates followed by slow cooling does not include a significant drop in hardness.

The thermostability of Creusabro® 4800 allows its use in aggressive environments up to 350°C (660°F).

This high performance wear resistant steel is suitable for all types of abrasion and is the best combination of improved workability and wear resistance.

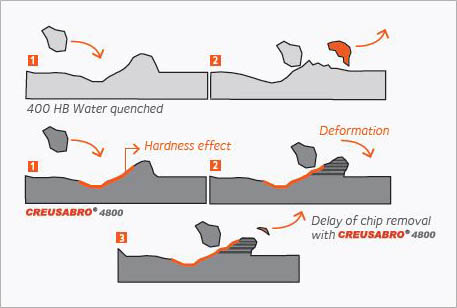

Abrasion / chip removal resistance :

Creusabro® 4800 has the advantage of a higher plastic deformation capacity on impact.

This improved ductility contributes to the chip removal of steel by abrasive particles, thus ensuring a slower rate of wear (weight loss) than conventional water-hardened steels.

| Main applications of Creusabro 4800 abrasion resistant steel | Indicative mechanical properties in the delivery state | Impact Energy | Dimensions and sizes available from stock |

|

|

|

3 to 150 mm :

Other sizes on request. |