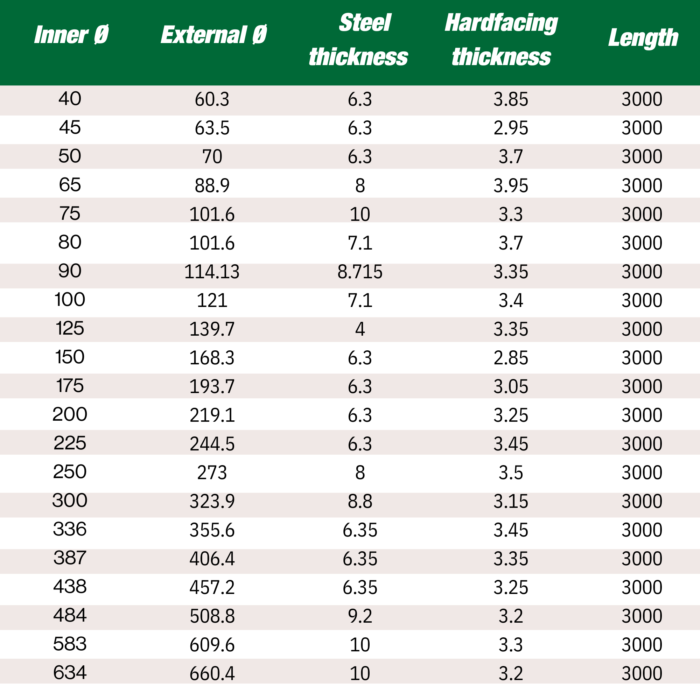

D31T Clad tubes

The Clad tubes are made by hardfacing of the inside diameter of a metal tube. The high chromium carbide content of the hardfacing gives them excellent resistance to abrasion. It is the ideal solution for making light and space-saving wear-resistant tubes. Pipes are generally subject to tangential wear by particles carried at high speeds.

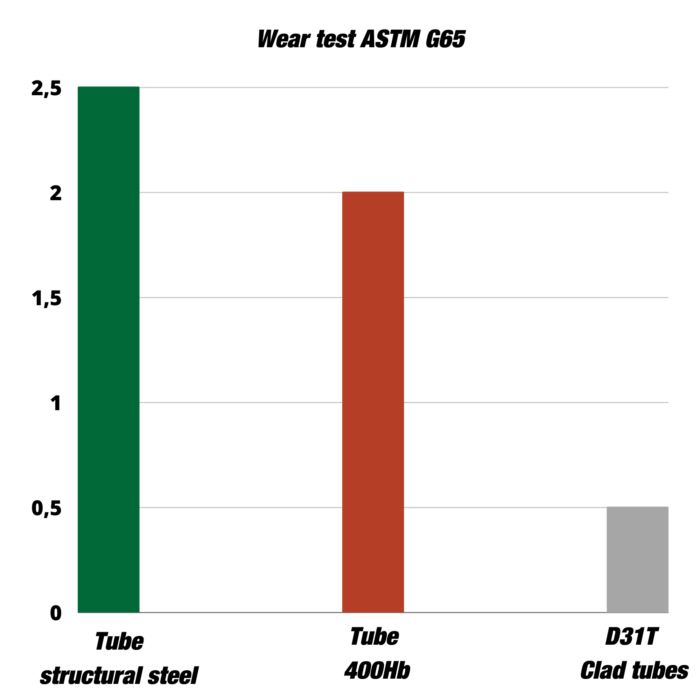

The use of tubes 400/500 Hb Quenched pipes is not recommended as it is not very relevant economically and in terms of service life, as abrasion resistant steel behaves like a structural steel when submitted at tangential wear (see table below, resistance to tangential wear). Hardness: 52-55 HRC.

Main applications of hardened wear resistant tubes

The hardfaced tubes are used in industrial applications such as piping for :

- Cement industry,

- Quarry,

- Foundry,

- Recycling,

- Incineration plant