Durgum: noise reducing wear resistant rubbers

Durgum range includes 3 grades which provide an effective response to the wear issues encountered in mining, quarrying industries, while greatly reducing the noise pollution associated with industrial activities.

DURGUM 650

Suitable for tangential abrasion from fine particles in wet environments, its high elasticity and sliding coefficient reduce clogging phenomena.

| Density | 1.10 |

| Shore hardness | 45 |

| Maximum working temperature | 80°C |

| Abrasion index according to DIN 53516 (mm3) | 130 |

DURGUM 680

Successfully used for highly abrasive crushed materials and in areas of high stress:

- High drop height

- High grain size

| Density | 1.12 |

| Shore hardness | 65 |

| Maximum working temperature | 80°C |

| Abrasion index according to DIN 53516 (mm3) | 90 |

DURGUM 550

| Density | 1.20 |

| Shore hardness | 65 |

| Maximum working temperature | 80°C |

| Abrasion index according to DIN 53516 (mm3) | 130 |

Economic compromise recommended for rolled materials or materials with low abrasiveness and moderately stressed areas: low flow rates, high percentage of fines, materials used discontinuously.

(*) DURGUM is a registered trademark of the company Produr.

Wear resistant property

Made from natural or synthetic rubbers with specific mineral fillers, DURGUM wear resistant rubbers have high elasticity and low abrasion indices.

Noise reduction, damping effect

The shock absorbing effect of DURGUM limits impact noise and reduces vibrations, thus preserving the noise environment in installations in suburban areas.

In components like feeders, hoppers and chutes, the shock absorbing effect prevents the formation of unwanted fines particules and preserves the original sizing of the processed material. The damping effect is provided by the product ALGUM, which is a wear resistant Alumina ceramic vulcanized on DURGUM rubber:

Areas of application of DURGUM

It is successfully used for lining or fabrication of :

- Chutes, silos

- Shot blasting machines

- Silters

- Screens

- Impact bars

- Belt lifts

- Vibratory feeders

- Skips

- Hydrocyclones

- Snow plough blades, scrapers

- Dumpers

- Primary or secondary hoppers

- Shredders…

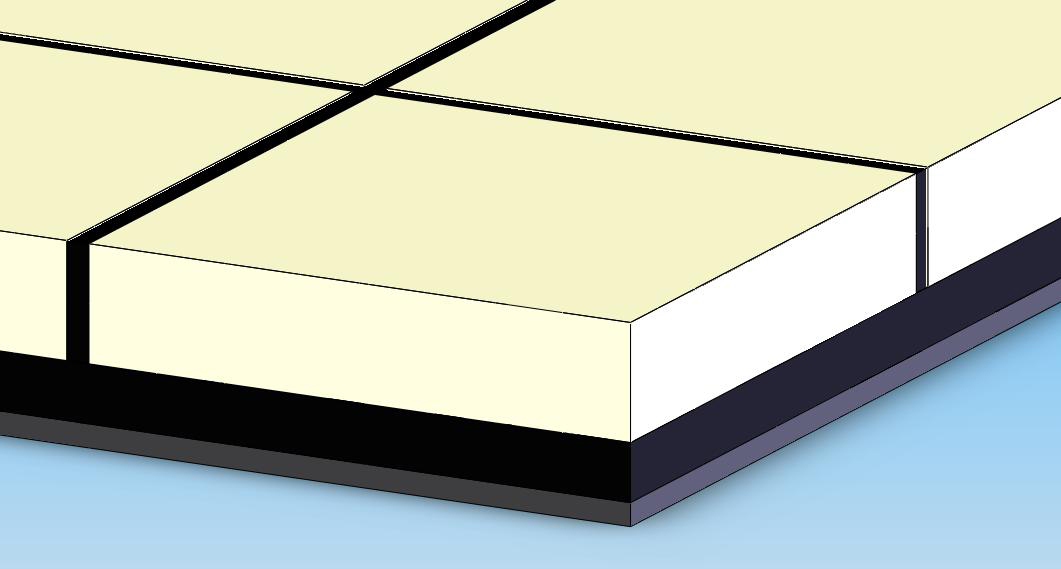

Fixings and implementation

DURGUM wear resistant rubbers are also available with various reinforcements, undercoats or supports to facilitate their application.

| DURGUM AD | Rubber with adhesive face |

| DURGUM RT | Rubber with textile reinforcement |

| DURGUM Vulcalu | Vulcanized rubber on aluminum profile or plate |

| DURGUM Vulcacier | Vulcanized rubber on steel profile or plate |

With a density 7 to 8 times lower than that of steel, reduces the stresses on plant structures and facilitates the installation of shoring elements.

These data are not contractual. PRODUR reserves the right to change the characteristics of its products at any time without prior notice.