Creusabro wear resistant steels

Discover CREUSABRO® wear resistant steels range :

The Creusabro® range is based on a different manufacturing process and metallurgy than the low carbon martensitic wear resistant steels.

Creusabro® wear resistant steels are designed to offer the best combination of wear resistance and processability:

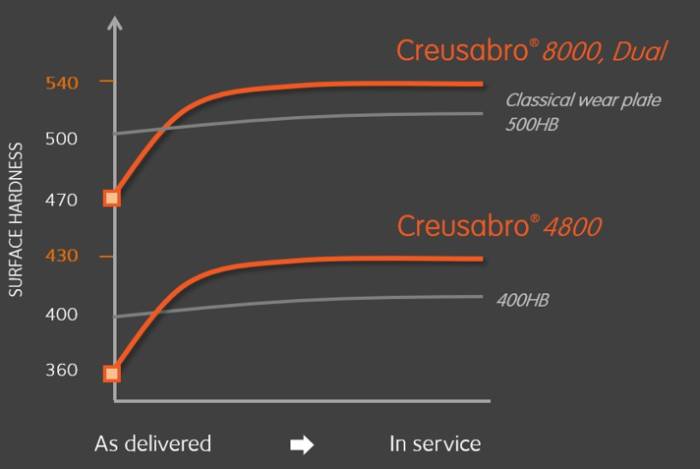

- Wear resistance in service is significantly improved by a surface hardening effect of +70 HB due to local plastic deformation caused by impact with rocks or pressure from abrasive particles. This reaction is known as the TRIP effect (Plasticity Induced Transformation).

- The moderate hardness in the delivery condition improve processability of complex parts in the workshop, without compromising the wear resistance in service applications.

- Due to its specific metallurgy, Creusabro® is heat resistant up to 450°C, which benefits from being hot worked without complicated heat treatment.

- Creusabro® has a high corrosion resistance, outperforming standard abrasion resistant steels in corrosive and abrasion affected environments.

Creusabro®, a gain in productivity:

Creusabro® plates are recognised worldwide and help to extend the life of mining equipment (mobile or fixed) or in many other industrial applications. Creusabro® abrasion resistant steels are particularly appreciated by end-users and workshops that recondition worn out equipment or produce wear parts. Creusabro® makes it possible to adapt buckets, crushers, etc. to the specific needs of each end-user, which improves the performance of the machines and therefore your productivity.

Creusabro® offers the perfect combination of wear resistance and easy processing for the most severe manufacturing and operating conditions.

Longer service life:

Long-lasting wear parts play an important role in achieving optimal operational performance and avoiding costly machine downtime. Creusabro® steels have proven to exceed the wear resistance of conventional water-hardened plates:

- The Creusabro® 4800 lasts 50 to 100% longer than conventional 400HB plates.

The Creusabro® 8000 and Dual last 50 to 100% longer than conventional 500HB hardness plates.

TRIP effect (Transformation Induced by Plasticity)

Produr will help you on your way to success with our extensive industrial experience and our teams of specialists who are there to support you.

We distribute worldwide services adapted to your needs and promote internal R&D to maintain a constant innovation approach.

THE CREUSABRO® RANGE OF WEAR RESISTANT STEELS:

Creusabro® 4800

Creusabro® 4800 abrasion resistant steel, the wear fighting choice

Creusabro® 4800 is a quenched & tempered steel that has been designed to ensure the best possible combination of wear resistance and easy processability. Abrasion resistance is improved by +70 HB in service due to a surface hardening effect (TRIP effect), provided by the action of impact or pressure.

- Thickness (mm): 3-150

- Hardness (HB): 370 in delivery conditions and 440 after work hardening.

- Main applications: wear parts, bucket linings, conveyors, hoppers, wear blades, bulldozers, screens, cyclones, grippers, etc.

Creusabro® 8000

Creusabro® 8000 abrasion resistant steel, the high performance choice

Creusabro® 8000 is an oil quenched wear resistant steel. Its properties are enhanced by the combination of an enriched alloying (chromium, nickel, molybdenum and titanium) and specific heat treatment processes. The moderate hardness of Creusabro ® 8000 in delivery condition makes processing operations such as cutting, machining and forming easier and much better than ordinary water-hardened steels.

- Thickness (mm): 4-60

- Hardness (HB): 470 in the delivery state and 540 after work hardening.

- Main applications: wear parts, bucket linings, conveyors, hoppers, wear blades, bulldozers, screens, cyclones, grippers, etc.

Creusabro® Dual

Creusabro® Dual abrasion resistant steel, the new generation steel

Creusabro® Dual is an advanced abrasion resistant steel with a high titanium content (0.6%). Compared to Creusabro® 8000, Creusabro® Dual is based on an innovative metallurgical concept, which is based on a specific chemical analysis. In addition, it is produced by oil quenching, which reduces the level of residual stresses occurring inside the part.

- Thickness (mm): 6-50

- Hardness (HB): 470 in the delivery state and 540 after work hardening.

- Main applications: wear parts, bucket linings, conveyors, hoppers, wear blades, bulldozers, screens, cyclones, grippers, etc.

Quality commitments

50 years of experience in the transformation of wear resistant steels have forged our professionalism and our understanding of these steels. Since our creation, our workshops have transformed more than 100’000 tons of abrasion resistant steels. As the first ambassador of quality abrasion resistant steels, we know how to select the best forges to build our range.

In accordance with our specifications, they are produced by ISO 9001 and ISO 14001 certified steel manufacturers. Produr requires its suppliers to comply with precise specifications (hardness, impact strength, tolerances, metallurgy, flatness, appearance, painting, marking and processability) before approval, their products are qualified internally (metallurgy laboratory), we do not make spot purchases or downgraded products, and our suppliers’ respect for the environment and CSR are taken into account in our purchasing policy. Each plate is checked internally on receipt (documentation, hardness, flatness, appearance, thickness), and batches are periodically sent to the metallurgy laboratory.