Dursteel Tuffplate – Wear resistant steel

DURSTEEL Tuffplate is a quenched and tempered steel with high abrasion resistance and a nominal hardness of 340 HB as well as very good toughness (impact resistance). Resistant to severe wear conditions or wear combining impact and abrasion, the extreme quality of the hardening and the specific metallurgy allow a good transformation of DURSTEEL Tuffplate, in particular a greater processability (oxyfuel cutting, weldability) than traditional 400 HB steels. It is a grade that is particularly appropriate for thicker components. DURSTEEL TUFFPLATE maintains its properties up to a temperature of 250°C. The use of DURSTEEL TUFFPLATE for heat treatment or hot dip galvanising is not recommended. For all uses of abrasion steels at higher temperatures, we advise you to use CREUSABRO product range or DURANOX 12.

| Main applications of Dursteel Tuffplate wear-resistant steel | Hardness | Mechanical properties |

Impact Strength |

Dimensions |

| Heavy duty wear parts for earthmoving and mining equipment, demolition tools, rock breakers. | 310-370 HB | Typical values Thickness 90 mm Rp 0.2 : 950 MPa Rm : 1000 MPa A% : 15 | Typical values Thickness 90 mm Impact energy 35 days at -40°C | Available in Quarto sheets : from 50 to 150 mm |

Recommanded welding wire for the Dursteel Tuffplate wear resistant steel welding :

- EASYCOR 70M : Slag-free copper-plated tubular cored wire for flat welding

- EASYCOR 70R : Slagged cored wire welded in any position

- EASYCOR 700M : High tensile strength copper-coated tubular cored wire for flat welding

- EASYCOR 700R : High strength pinch cored wire for welding in any position

- CORINOX 307G : Stainless steel cored wire for heterogeneous assembly

- CORINOX 312G : Stainless steel cored wire with high mechanical properties for heterogeneous assembly

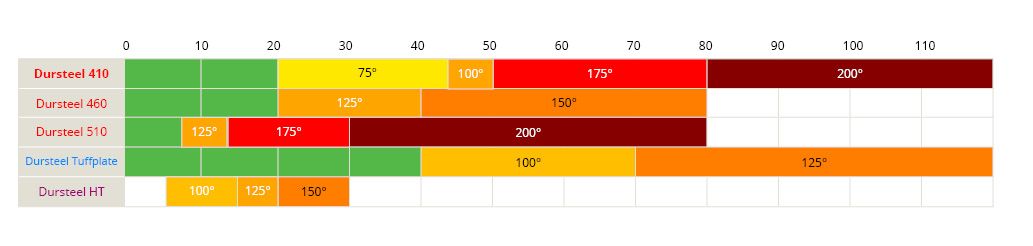

Recommended minimum preheating and inter-pass temperatures depending on thickness in mm