DURSTEEL 460 – Wear resistant steel

DURSTEEL 460 is a quenched and tempered abrasion resistant steel with a nominal hardness of 460 HB. It endures severe wear and tear and its high yield strength allows it to absorb high impact loads without deformation. In addition to its hardness and toughness characteristics, DURSTEEL 460 wear-resistant steel can be easily processed due to its high quenching quality and is characterized by good processability (bending, machining, welding).

Application of wear-resistant steel 460HB

This wear-resistant steel has excellent rolling, crunching and bending properties. DURSTEEL 460 maintains its properties up to a temperature of 250°C. The use of DURSTEEL 460 for heat treatment or hot dip galvanizing is not recommended. For all uses of abrasion steels at higher temperatures, we recommend the use of our Creusabro grades or DURANOX 12 steels. DURSTEEL 460 is a Q&T steel with a low carbon equivalent allowing good weldability. However, some precautions must be taken when welding. Preheating is recommended for thicknesses of 20mm and above.

| Main applications of Dursteel 460 wear-resistant steel | Hardness | Mechanical properties of Dursteel 460 | Impact Energy | Dimensions and sizes available from stock |

| Dumpers, grabs, wear blades, buckets, sprockets, hoppers, chutes, hammers, knives, bulldozers, augers, screens, grabs, etc… | 420-480 HB | Typical values, 20mm thick :

|

Impact energy 45 days at -40°C |

|

Recommanded filler metals for Dursteel wear resistant steel welding :

- EASYCOR 70M : Slag-free copper-plated tubular cored wire for flat welding

- EASYCOR 70R : Slagged cored wire welded in any position

- EASYCOR 700M : High tensile strength copper-coated tubular cored wire for flat welding

- EASYCOR 700R : High strength pinch cored wire for welding in any position

- CORINOX 307G : Stainless steel cored wire for heterogeneous assembly

- CORINOX 312G : Stainless steel cored wire with high mechanical properties for heterogeneous assembly

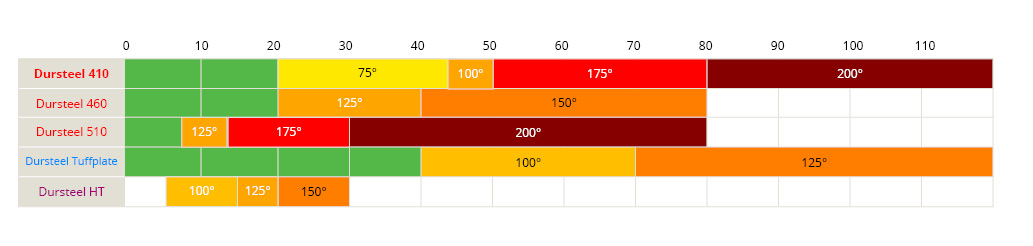

Recommended minimum preheating and inter-pass temperatures depending on thickness in mm