Durcast wear blocks achieves the impossible: Combine high alloys white cast iron with very high wear resistance easily weldable.

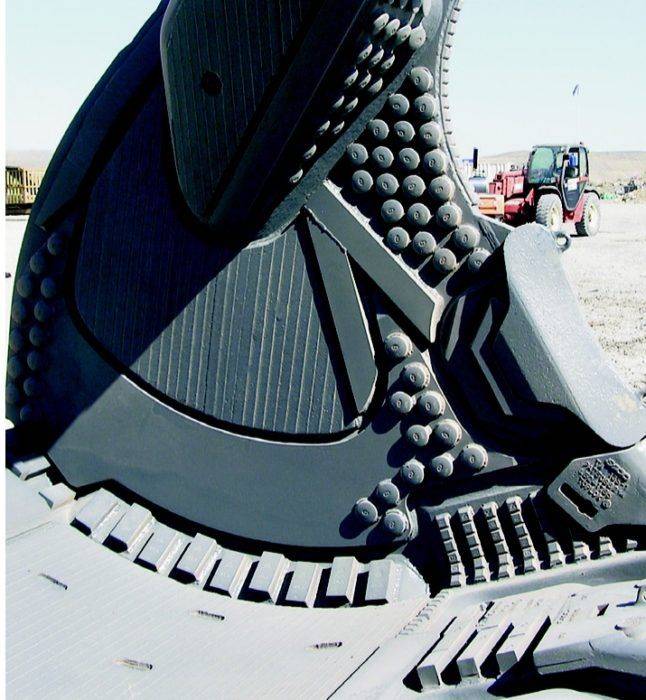

DURCAST WEAR BLOCKS APPLICATION AREAS

Durcast blocks are particularly adapted to protect severe and small areas against abrasion :

- stone boxes,

- slide rails,

- crushing equipment,

- sliding blocks,

- tooth holders,

- bucket bottoms,

- belt jetties,

- sides of shredders,

- scraping blades,

- trenchers,

- impact zones,

- areas of severe abrasion under high stress,

- etc…

Characteristics of the DURCAST® wear block

Part of the range of high performance materials selected by PRODUR and whose common characteristic is to be easily implemented, the DURCAST wear block is made of cast iron blocks with chromium molybdenum, associated by a metallurgical bond to a weldable base in S235 steel.

High alloys white cast iron, exceptional in hardness and wear resistance, is almost impossible to weld and difficult to bolt due to its fragility. S235 steel is a material that is easy to work with but has poor wear resistance performance. By combining them through a special process, we obtain the DURCAST composite which benefits from the positive properties of each material:

S235 base material :

- Easy to weld, even with abrasion resistant steels such as DURSTEEL

- Machinability

- Easy forming

- Ability to absorb shocks (shock absorber function)

For the white cast iron block:

- Very high wear resistance

- Perfect behavior to abrasion under high stress

- Resistance to corrosive environments due to the chromium content

- Specific shapes obtained by casting

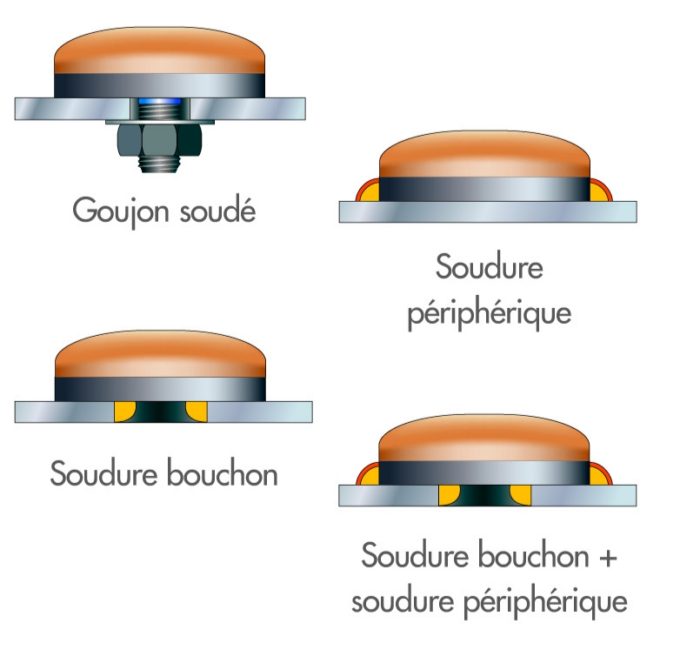

HOW TO FIX THE DURCAST WEAR BLOCK

The peripheral welds of the wear block must be protected:

- Either by positioning the elements in such a way as to prevent the movement of abrasive material on the weld (staggered assembly)

- Or by using DURCOR tubular electrodes as a final protection pass

- Or by combining the two techniques.

The bonding of the two components is achieved by brazing at high temperature in a furnace under an inert gas atmosphere, using a copper-based alloy. It should be noted that the breaking strength of the metallurgical bond (>250 MPa) is higher than the yield strength of S235 steel. There is therefore no risk of separation between the cast iron block and its support.

STANDARD SIZES FOR DURCAST WEAR BLOCKS

For particular applications and within the limits of production capacity, it is possible to produce specific parts or sizes

Discs size

- Ø 75

- Ø 90

- Ø 115

- Ø 150

Standard wear blocks size

- 200x25x25

- 300x25x25

- 75x50x32

- 150x50x50

- 230x50x50

- 432x50x50

Bars size

- 240x40x23

- 240x50x23

- 240x65x23

- 240x90x29

Skid blocks size

- 200x150x45

- 250x150x45

- 250x250x45

Mechanical characteristics of the Durcast wear block

| Base | Mild steel type S235 |

| Cast iron | White martensitic cast iron grade CrMo 15-3 Average hardness 700 HV 50 Die hardness 650 HV 0,5 Carbide hardness 1300 HV 0,3 Carbide volume 30% minimum |

| Joint | Copper base under inert atmosphere Mechanical resistance > 250Mpa |