Duraplate D45T high temperature wear plate

DURAPLATE D45T is a clad plate with stringer weld beads. Its complex carbide coating gives it a very high resistance to abrasion and temperature up to 600°C. It combines the exceptional wear resistance performance of its chromium carbide coating with the flexibility of its mild steel base material. This last characteristic allows an easy implementation: cutting, rolling, welding… DURAPLATE sheet responds efficiently to the most severe abrasion conditions.

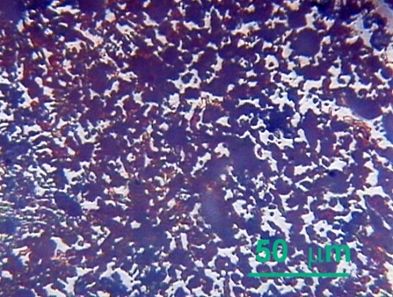

Chromium carbide and complex carbides (Niobium, Molybdenum, Tungsten and Vanadium) in a carbide matrix for high temperature hardfacing.

DURAPLATE is made up of a deposit of CHROMIUM CARBIDE on a mild steel support plate. This very hard deposit is made by parallel beads welded to the base metal. These continuous beads are also fused longitudinally, which results in a very flat and homogeneous surface.

The clearly visible cracks, perpendicular to the weld beads, are shrinkage cracks which prove that the stresses due to the deposit have been released. They don’t affect the performance of the material. Their location is limited to the hard layer. They do not propagate in the base metal.

Wear plate hardfaced with stringer beads

The welding process by stringer beads, a particularity of the Duraplate wear plate, allows to obtain :

- more homogeneous hardfacing metallurgy (finer carbides due to fast cooling process)

- more constant hardfacing layer thickness,

- finer and better distributed cracks,

- low dilution in the support plate.

These four elements give Duraplate grades a wear resistance superior to that obtained by conventional hardfacing processes. This specific process implemented by Welding Alloys Group allows superior control of the dilution zone, reduce the weakening of the base plate and the risk of cracks during forming.

Applications of High Temperature Wear Resistant D45T

- Forming: the exceptional quality of Duraplate high temperature hardfacing makes it suitable for cold forming according to specifications which depend on the combination of the thickness of the hardfacing and the support sheet. The sheet heated to more than 1200°C can be hot-formed without changing its characteristics.

- Areas of use: components subject to heavy wear and high temperatures, steel industry, cement industry, recycling, thermal power plants, asphalt plants.

- Welding: all conventional welding procedures apply to Duraplate. Hardfacing can be repaired or completed with DURCOR electrodes or wires of the same composition as the filler metals.

| Thickness (mm) Base plate + Hardfacing | D45T Dimensions |

| 5+3 | 2900 x 1900 |

| 6+4 | 2900 x 1900 |

| 8+5 | 2900 x 1900 |

| 10+9 | 2900 x 1900 |

- Other dimensions on request

- Hardness of the D45T high temperature plate: 62-64 HRC